So I stripped the engine down to the bolts, taking lots of pictures along the way (most of them ill lit and poorly focused). I found the digital camera to be one of the most useful tools in my arsenal at this time. I would lay the bolts out and photo the configuration to make sure I got them all back in the right holes.

Poorly lit, yet focused. Points deducted for shooting your own toe.

The pistons were pretty crapped up with carbon and gunk. I’ve heard tell of folks tossing pistons for this very reason, but rest assured; a good wire brush and some mineral spirits will work wonders on a gunked piston. Same for the valves.

I brought all the aluminum to a local guy who made a living sand blasting old truck engines clean. He worked me into his schedule for about $70 and blasted my whole engine, piece by piece. Once I got the case parts back, they looked factory new…almost too new. I finished them with rattle can VHT high temp engine paint and baked the parts in my mom’s oven. This, I should note, will not directly improve your relationship with your mom, or her oven, or the house, which reeked of burning chemicals for a day and a half.

...And yet from such anguish emerges beauty, like flowers from a skull...or a tattoo of flowers coming out of skulls.

As shown in the photopragh above, I painted the side covers with silver wheel paint. It’s rated to 400 degrees and the engine covers seldom get that hot. Plus VHT is, like, ten bucks a can, and I’m on a budget here.

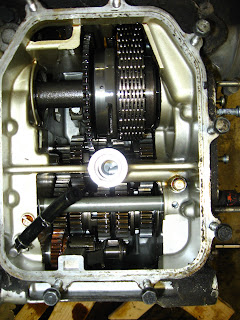

I honed the cylinders (probably the easiest yet hardest sounding part of rebuilding an engine) and the valve seats and then began the somewhat daunting task of putting the whole kit and caboodle back together. Somewhere in that process, I discovered that all the contact surfaces on my valve cam and tappets were shot. I believe these things are case hardened, which means the metal surface is only hard for the first 1/16th to 1/8th of an inch. The core of the casting is still unhardened steel. This is actually a good thing for two reasons: one, it reduces the brittleness of the part, yet still allows it to be used in services which require hardening. Think of the traditional Japanese sword, which is comprised of three different hardnesses of metal for the spine, body, and edge of the blade. Well, a case hardened cam shaft is just like that…except it’s two metals, not three…and it’s a cam shaft, not a sword. But still Japanese, in the case of the Honda.

In 'case' there is still some confusion

Second, case hardening gives the consumer a much cheaper product, as it does not require extensive heat treating time and labor in the production facility. Which leads me to digress: I find it amazing that we can buy these motorcycles brand new for around $5000. Take one apart some day and just look at all the engineered parts in these things. It’s incrediculous.

All case hardening nerd-dom aside (and please correct me if I’m wrong on any of the above purported facts) my case hardening on my cam shaft had bit the dust. I think some joker might have run it with low (or no) oil one day. The lobes were pitted and scarred, and the tappets (most likely as a result) were all beveled and worn. I hit ebay and managed to scrounge up a new shaft and tappets for around $40. Interestingly, they were selling individual used tappets for $30 a pair, but I bought the entire valve cover assembly (with eight tappets installed) off a fine gentleman for five dollars less. Win.

I kept the original piston rings except for one set (which I broke when trying to remove them. I’m wondering to this day if I should have just gone nuts and replaced the whole lot of them when I had the engine apart. However, I had it on good authority (my dad, who used to build and race Fiats in the SCCA circuit) that the rings were good, so I just reinstalled them and wished for the best. We’ll see.

I resisted a good deal of temptation on this engine. There were plenty of high compression pistons, racing cams, and big bore kits calling my name. But as this is my first real build, I decided to run it stock (well, mostly, it has an oil cooler adapter, and the carb might be jetted, but I'm not sure). When I can get the basic machine purring and whirring, I'll think about throwing in some hop-ups.

I resisted a good deal of temptation on this engine. There were plenty of high compression pistons, racing cams, and big bore kits calling my name. But as this is my first real build, I decided to run it stock (well, mostly, it has an oil cooler adapter, and the carb might be jetted, but I'm not sure). When I can get the basic machine purring and whirring, I'll think about throwing in some hop-ups.

At the end of…I think it was a year (I was in college at the time of this rebuild, if memory serves) I had a finished CB550 engine sitting on a board mounted to the unused foosball table in the basement. The motor was clean, it had good compression, and it looked pretty to boot.

This was all well and good at the time, as I was still focused on building a pretty bike at the time. But as in all good thrillers, what started off sunny and bright was about to take a turn for the gritty and visceral.

Fig. 21: Pretty

This was all well and good at the time, as I was still focused on building a pretty bike at the time. But as in all good thrillers, what started off sunny and bright was about to take a turn for the gritty and visceral.